The motor drives the reducer, and the reducer drives the eccentric wheel to make the plunger reciprocate linearly in the pump body, and sequentially realize the oil absorption and oil discharge process.

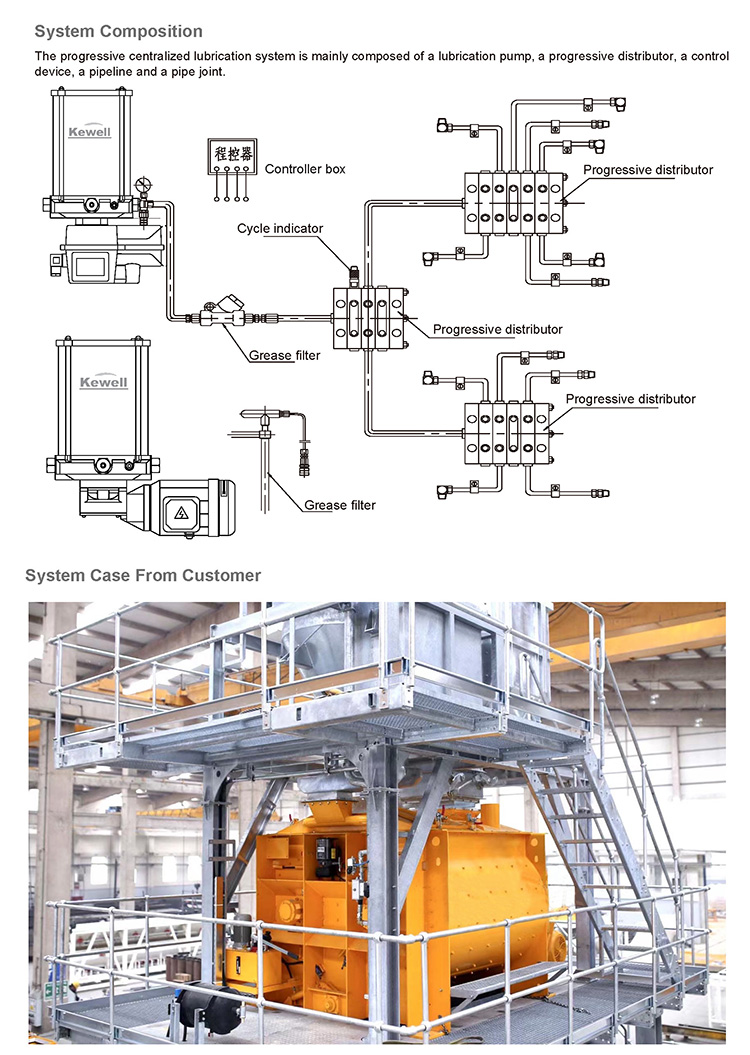

1. There are (1-5)independent pump units on the compact lubricator, canbe combined with the progressive distributor to form a progressive grease lubrication system to supply grease to lube points ,or lube the pointsdirectly,This is an economical way to save the cost and service expenses.

2. The motor is fully sealed and has the advantages of water proof and dustproof.

3. The pressure is up to 25MPa, each outlet has a safety valve to prevent the pump unit from overloading.

4.Each outlet standard flow can choose :1.8cc /min , 5.5cc/min

(Option: You can assemble aseismatic pressure gauge to monitor the whole lubrication system) Standard flow for each outlet is optional :1.8cc/ min,5.5cc/ min,

5.Power input for different customer demand :220VAC/50Hz,380VAC/50Hz, or 24VDC.etc.(Option:can buit-in controller which can setting working time and down time.)

Provide power input according to different customer requirements: 220VAC/50Hz, 380VAC/ 50Hz or 24VDC.

6. Low level switch, can achieve low liquid level alarm (You can choose toinstall )

7. PCL control the cycle time: Running time and interval time (You canchoose to install )

8. A variety of volume tank selection, tanks have metal and plastic tankselection.

9.A sealed plastic shell covers the main electrical elements, and provides good protection to meet different rough condition.

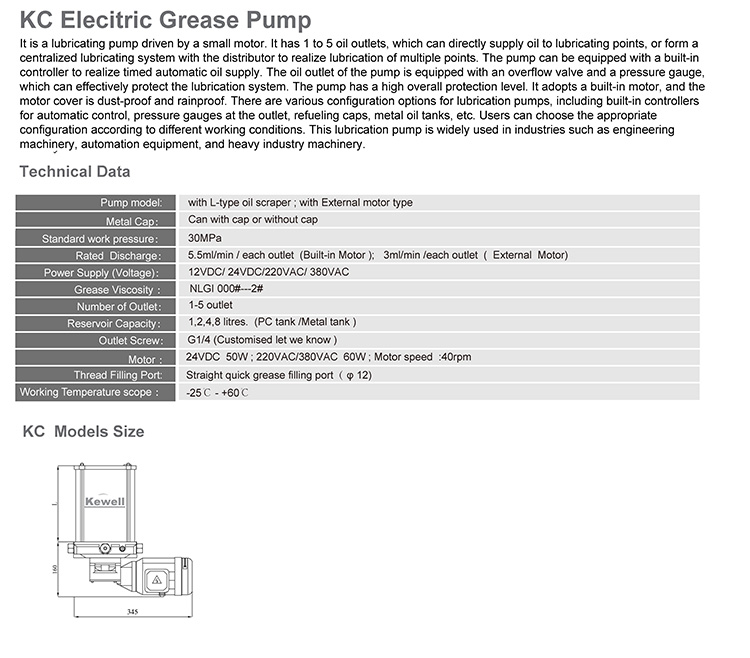

KC Elecitric Grease Pump

It is a lubricating pump driven by a small motor. It has 1 to 5 oil outlets, which can directly supply oil to lubricating points, or form a centralized lubricating system with the distributor to realize lubrication of multiple points. The pump can be equipped with a built-in controller to realize timed automatic oil supply. The oil outlet of the pump is equipped with an overflow valve and a pressure gauge, which can effectively protect the lubrication system. The pump has a high overall protection level. It adopts a built-in motor, and the motor cover is dust-proof and rainproof. There are various configuration options for lubrication pumps, including built-in controllers for automatic control, pressure gauges at the outlet, refueling caps, metal oil tanks, etc. Users can choose the appropriate configuration according to different working conditions. This lubrication pump is widely used in industries such as engineering machinery, automation equipment, and heavy industry machinery.